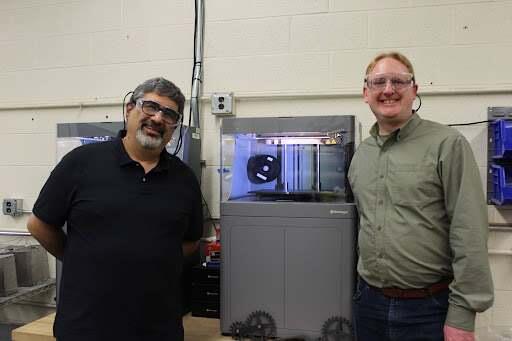

When Alan Bolind walks into a lab, he’s not just inspecting equipment — he’s laying the foundation for a safer research environment. As a lab safety specialist (LSS) for UC Berkeley’s Office of Environment, Health & Safety (EH&S), Bolind works closely with department safety coordinators (DSCs), like Amin Jazaeri, to ensure that safety isn’t just a checklist item, but a shared culture. Jazaeri, who oversees high-risk machinery in the Mechanical Engineering Student Access Machine Shop, knows that safety depends on constant awareness and collaboration. “The students are working with machines that, if they’re not paying attention, could be deadly,” Jazaeri said. In spaces filled with heavy machinery, 3D printers, and waterjet cutters, collaboration and communication between EH&S and DSCs can make the difference between routine research and a serious safety incident.

Bolind conducts inspections across labs in the College of Engineering and the Department of Physics. He identifies potential safety concerns and helps researchers address them. He annually schedules walkthroughs with professors or lab safety coordinators, documents his findings, and works collaboratively to ensure any issues are resolved.